Bottle washing machines have become indispensable in industries such as food and beverage, pharmaceuticals, and packaging. They efficiently clean and sanitize containers, ensuring safety, hygiene, and sustainability in production processes.

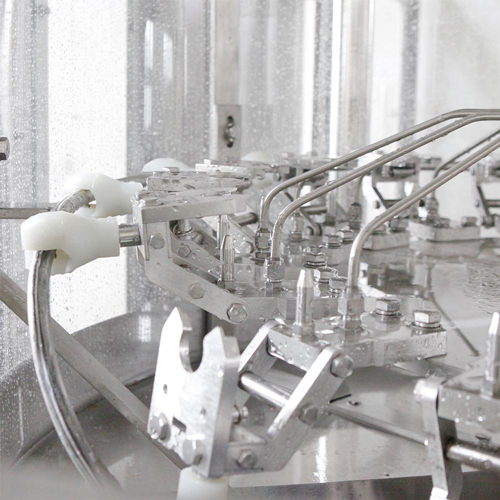

These machines employ advanced mechanisms, including ultrasonic cavitation and high-pressure water jets, to remove impurities from bottles. Ultrasonic systems utilize bubble bursts to dislodge dirt and residue effectively, while automated sterilization ensures thorough cleanliness.

Benefits of Bottle Washing Machines

1. Cost-Effective : They reduce labor costs and optimize cleaning efficiency.

2. Wide Range of Applications : Adaptable for various bottle types, from glass to plastic, across industries.

3. Hygiene Assurance : Integrated sterilization and drying features ensure that bottles meet high sanitary standards.

4. High Output Capacity : Machines like the Nilo Single End can wash up to 80,000 bottles per hour, catering to large-scale operations .

As sustainability becomes a global priority, bottle washing machines will evolve to support eco-friendly practices, such as water recycling and reduced energy consumption. Their role in promoting reusable packaging is pivotal to reducing environmental impact.