In the modern furniture manufacturing industry, spring mattresses have always been favored by consumers as a classic and comfortable choice. The production of spring mattresses involves multiple complex processes, among which spring mattress production machines play a vital role.

The basic working principle of spring mattress production machines

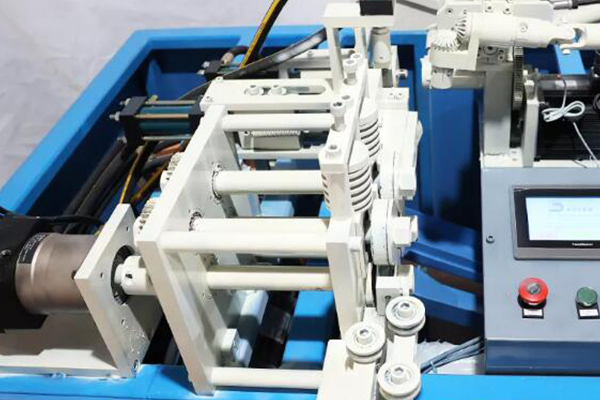

Spring mattress production machines are mainly used to manufacture spring components in spring mattresses. Its core functions include weaving, shaping and assembly of springs. The typical production process includes the following steps:

1. Spring winding: The machine winds the steel wire into the basic shape of the spring through a precise mechanical device. This process requires precise control of the tension and density of the winding to ensure the elasticity and durability of the spring.

2. Spring heat treatment: After winding, the spring will undergo a heat treatment process to improve its strength and stability. This process usually includes heating and cooling stages to ensure the performance of the spring in long-term use.

3. Spring assembly: The treated springs will be neatly arranged and fixed on the frame of the mattress. This link requires high-precision operation to ensure the uniform distribution of the springs, thereby providing consistent comfort.

4. Mattress packaging: Finally, the spring mattresses are inspected and packaged before being shipped to the market.

As an important part of modern furniture manufacturing, the continuous innovation and progress of spring mattress production machines are changing the way and quality of mattress production. With the continuous development of automation, intelligence and environmental protection technologies, the future spring mattress production will be more efficient, precise and environmentally friendly, providing consumers with a better sleeping experience. At the same time, these advances will also drive the entire industry to a higher standard and more sustainable direction.